EMI, EMP & HEMP Solutions for Critical Infrastructure

Shielding products and services to maintain a resilient critical infrastructure.

About Us

Solving the Complexities of Electromagnetic Shielding

For over 40 years Gaven has established itself as the leader and expert in complex shielding; offering wide-spanning expertise throughout the 16 critical infrastructure sectors, including public and private entities. Gaven’s HEMP structures are used to help maintain a resilient critical infrastructure. We have partnered with energy companies, telecom providers, data centers, water & and wastewater, transportation, and more.

What We Offer

Comprehensive Shielding Protection for Critical Infrastructure

- In-house drafting and modeling

- Products designed to meet and exceed test standards

- Lifecycle survivability analysis

- A/E & prime contractor partnership

- Complete BIM coordination

Testing Services

- Acceptance & Verification test capabilities

- Lifecycle Capabilities such as preventative maintenance services and Hardness Surveillance

Installation, Integration & Construction

- Periodic Inspections

- Performance Evaluations

- Preventative Maintenance

- Repair & Restoration Services

- Upgrade Implementation

- Document & Reporting

Threats to Critical Infrastructure

“Whether caused by man or nature, electromagnetic pulse (EMP), geomagnetic disturbance (GMD), and other electromagnetic interference (EMI / IEMI) events have the potential to disrupt and permanently damage electrical components and entire systems within most critical infrastructure sectors and impact large-scale infrastructure. While EMP hardening standards exist for military applications, they are often too case-specific, expensive, and impractical for the private sector to implement, leading to very little action being taken to address this threat, despite it having the potential to affect the nation at large.”

– Department of Homeland Security, Office of Science and Technology

What We Protect Against

HEMP/EMP Vulnerabilities

While no utility infrastructure system or process is a true single point of failure, the ability to meet service delivery needs starts within the SCADA or operations center. These facilities greatly benefit from strategic planning and tactical implementation of an EMP and EMI protection plan.

The ability to operate through an electromagnetic event such as EMP, HEMP, or IEMI depends on the availability of power. To power your critical systems and processes through a power interruption, a generator can only guarantee continuity if the processor-controlled systems are adequately shielded and filtered.

No critical infrastructure mechanism or operation is at greater risk from EMP, IEMI, GMO, or even physical destruction than our nation's substation and utility delivery systems. These crucial sites can be protected by even basic risk-mitigation steps

Critical assets such as equipment and subsystems are those that, if damaged, can significantly impair an organization's ability to safely meet production requirements or negatively impact delivery and quality level. Shielding and protecting these sites offer a comprehensive E-threat risk. mitigation strategy.

In the event of an EMI/EMP, maintaining public safety and the ability to recover relies on the availability of survivable equipment. Whether hardened or stored as spares, these critical components and electronics are needed to preserve human life and repair critical systems.

What We Offer

Shielding Solutions for Critical Infrastructure

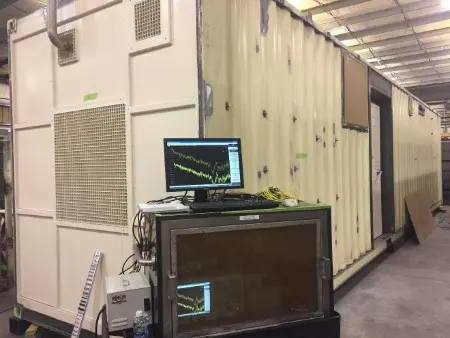

Gaven’s HEMP-shielded Modular Enclosure System is designed to rapidly deploy a HEMP-shielded structure or enclosure that is proven to meet or exceed stringent EMI and RFI shielding requirements such as those within MIL-STD 188-125-1/-1A/-2 and NSA 94-106.

The Modular Enclosure System uses three main components to assemble a facility system that is scalable to mission or operational needs.

- Enclosures

- Vestibules

- Flexible connecting links

Modular Shielded Structures

Enclosures

Vestibules

Flexible Connecting Links

Enclosures

Vestibules

Flexible Connecting Links

Gaven’s HEMP-shielded Modular Enclosure System is designed to rapidly deploy a HEMP-shielded structure or enclosure that is proven to meet or exceed stringent EMI and RFI shielding requirements such as those within MIL-STD 188-125-1/-1A/-2 and NSA 94-106.

The Modular Enclosure System uses three main components to assemble a facility system that is scalable to mission or operational needs.

- Enclosures

- Vestibules

- Flexible connecting links

Modular Shielded Structures

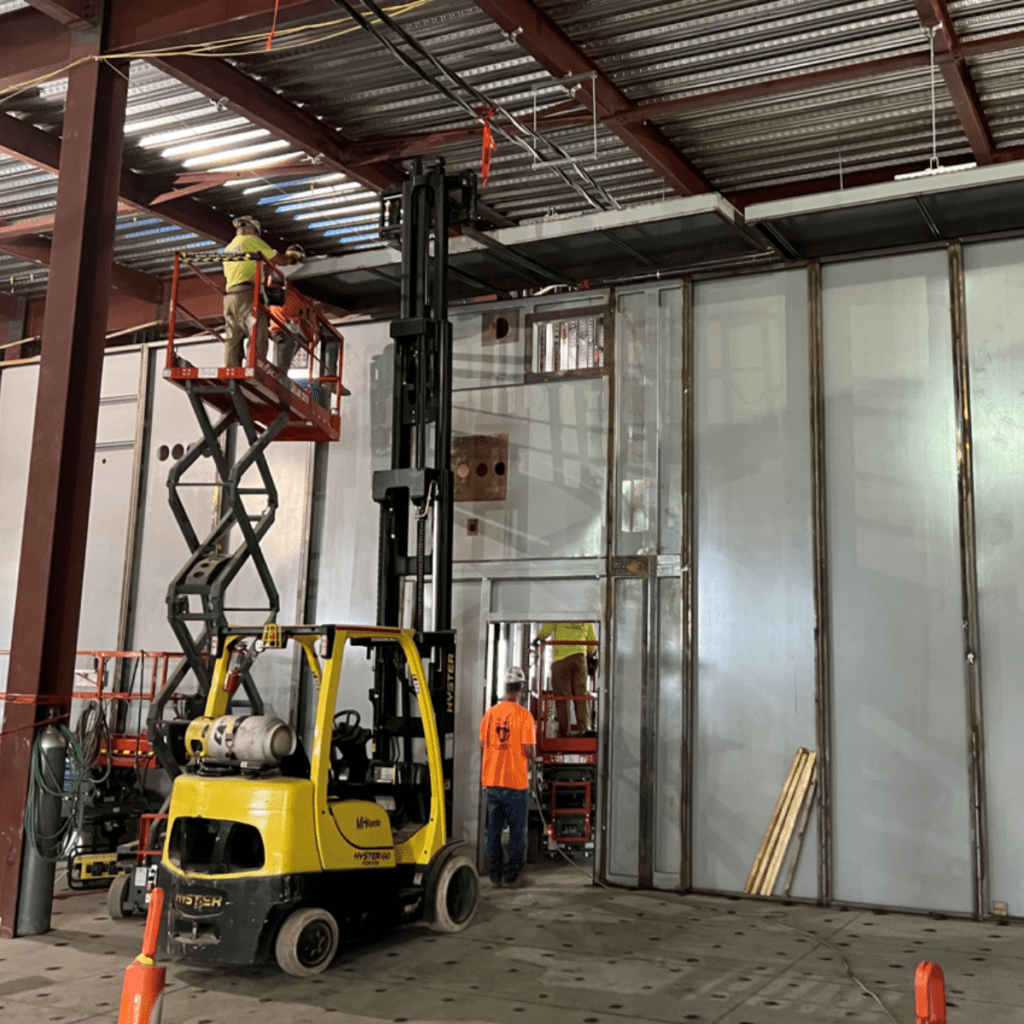

Prefabricated Fixed-Site Structures

The installation of shielding for an entire facility after the envelope is complete can take significant time. The traditional stick-build method is both costly and time-consuming on-site. Gaven’s approach is a prefabricated system that can integrate the shielding directly into the envelope itself, so when the facility envelope is complete, the shielding is also complete. This approach, using steel-form tilt-up panels utilizes methods that are familiar to many general contractors and adds a welding step for seams of the tilt-up panels to integrate the shielding with adjacent walls, floors, and ceiling panels.

Shielded Transportable Containers

In the wake of an IEMI, EMP, HEMP, or large-scale GMD event, portable electronics, power tools, communication equipment, and life-saving medical devices will cease to operate. Protecting these critical items is essential to minimizing impact post-event. Gaven’s HEMP-Shielded Transportable Containers are tested to meet both military and ISO standards – mitigating threat and risk concerns and ensuring the resiliency of microgrids, as well as small-unit and community operations.

Critical Backup Power Generation

A simple generator to power your critical systems and processes is not enough in case of power interruption resulting from an EMP event. Gaven offers multiple power generator options that are HEMP protected with filtered power. Gaven’s standard offering of both transportable and semi-permanent fixed-site Tier 4 Final generators are available from 60 kW to 600 kW. We also offer custom solutions for even smaller generators and have routinely shielded 1 MW generators. Gaven has deep experience in deploying large format generators and generator structures in many different verticals including utilities such as energy, water, oil & gas, and more.

About Us

Gaven Industries specializes in EMI, EMP, HEMP, and RF shielding solutions, including expertly crafted doors, shielded structures, rooms, and data racks.

Quick Links

Stay Informed

Subscribe for exclusive updates

and insights from Gaven Industries.

Copyright © 2024 Gaven Industries Inc. All Rights Reserved.