Testing Services

About Us

Precision, Expertise, & Innovation

in Every Test

At Gaven Industries, we offer a comprehensive suite of electromagnetic shielding testing services designed to ensure the integrity, effectiveness, and compliance of your shielded enclosures and components. With decades of experience and a commitment to excellence, our team leads the industry in identifying, developing, and applying advanced testing methodologies. Explore our testing services to discover how we can support your project from inception to completion and beyond.

What We Offer

Electromagnetic Shielding Testing Services

Understanding that shielded enclosures are critical to your operations, Gaven Industries provides lifecycle and periodic testing services to identify potential failures or degradation before they impact your mission. We meticulously evaluate all critical items and processes, recommending and conducting necessary maintenance practices to ensure ongoing reliability and performance.

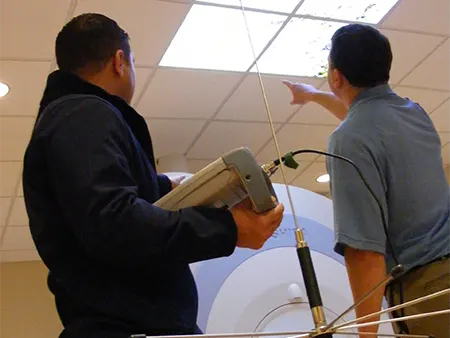

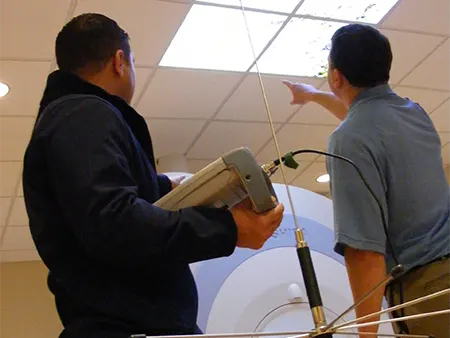

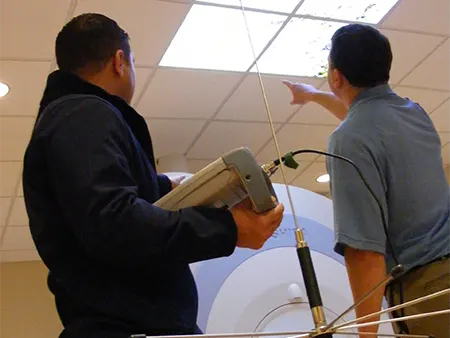

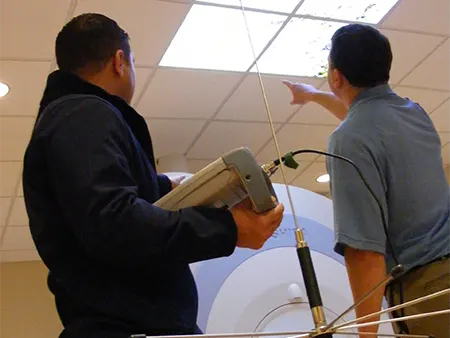

Our Shielding Effectiveness Testing is at the forefront of ensuring your enclosures can effectively block electromagnetic and radio frequency interference. Leveraging years of experience, we've optimized our test methodologies to deliver fast, accurate results, helping you maintain the highest standards of protection without compromise.

At Gaven Industries, we specialize in PULSE Current Injection Testing to evaluate the resilience of your electrical Point-of-Entry (POE) protective devices against externally generated threats, such as EMPs. Our custom-designed pulse generators produce MIL-STD-188-125-compliant waveforms, allowing for comprehensive testing of various filter types and RF POEs, ensuring your facilities are safeguarded against high-energy events.

Our CWI Testing method measures the electromagnetic responses of barriers and associated items, such as cables or conduits, when exposed to continuous-wave electric or magnetic fields. This precise testing helps in understanding and improving the protective measures of your electromagnetic barriers.

Our Upgrade Implementation service at Gaven Industries is specifically designed to ensure your shielding systems stay advanced in a landscape where technology and threats are constantly evolving. We assess and upgrade your solutions with the latest, most effective materials and cutting-edge technologies. This not only boosts the performance and security of your systems but also extends their lifespan and adapts to future challenges, keeping you one step ahead in electromagnetic protection.

To comply with regulatory standards and ensure the enduring integrity of HEMP-shielded enclosures, Gaven Industries offers recertification testing services. We assess the ability of your enclosures to withstand EMP occurrences, maintaining their certification and safeguarding your assets.

Other Services We Offer

Beyond Testing: Maintenance & Design Services

Explore the full spectrum of Gaven Industries’ offerings beyond testing, including Maintenance Services and Design & Consultation. Our proactive maintenance ensures your electromagnetic shielding remains in peak condition, offering regular inspections and necessary upgrades. Our design and consultation services work from the ground up, crafting bespoke strategies to integrate seamless protection into your projects, ensuring they are both effective and efficient. Together, these services form a complete ecosystem of support for any shielding challenge.

- Periodic Inspections

- Performance Evaluations

- Preventative Maintenance

- Repair & Restoration Services

- Upgrade Implementation

- Document & Reporting

- Electromagnetic Shielding Design

- Product Design Consultation

- Design Validation & Modeling

- EMC Strategy Development

- Regulatory Compliance Consulting

- Risk Assessment

Other Services We Offer

Beyond Design: Testing & Maintenance Services

Explore the full spectrum of Gaven Industries’ offerings beyond Design & Consultation, including Testing and Maintenance services. With our proactive maintenance approach, we provide regular inspections, performance evaluations, and timely upgrades to maintain peak condition and effectiveness of your shielding. Our testing services, from lifecycle and periodic testing to specialized shield effectiveness and compliance tests, guarantee that your projects meet the highest standards of protection and regulatory compliance. Together, these services ensure your shielding challenges are met with unmatched precision and care.

Maintenance Services

- Periodic Inspections

- Performance Evaluations

- Preventative Maintenance

- Repair & Restoration Services

- Upgrade Implementation

- Document & Reporting

Design & Consultation

- Electromagnetic Shielding Design

- Product Design Consultation

- Design Validation & Modeling

- EMC Strategy Development

- Regulatory Compliance Consulting

- Risk Assessment

Precision Testing Across Sectors

Gaven Industries conducts rigorous Shield Effectiveness Testing and Pulse Current Injection Testing for the Government & Defense sector, ensuring systems are safeguarded against EMI threats and compliant with security standards. Lifecycle & Periodic Testing and Recertification Testing are pivotal in maintaining operational integrity over time.

Our Lifecycle & Periodic Testing and Shield Effectiveness Testing are crucial for Medical and Healthcare equipment, like MRI machines, to prevent EMI disruptions and ensure patient safety and diagnostic precision.

In the Test, Measurement, and R&D sector, Continuous-Wave Immersion Testing and Pulse Current Injection Testing enable accurate data collection and innovation by ensuring an EMI-free research environment.

For Data Centers and Critical Computing, Shield Effectiveness Testing and Recertification Testing ensure the integrity and continuity of operations, protecting against data loss and service interruptions.

Gaven Industries specializes in protecting Data Centers and Critical Computing infrastructures from electromagnetic interference. Our comprehensive services ensure the integrity and continuity of operations, safeguarding against data loss and service interruptions. With our expertise, your data remains secure and your computing services remain uninterrupted.

Learn More >

Industries We Protect

About Us

Gaven Industries specializes in EMI, EMP, HEMP, and RF shielding solutions, including expertly crafted doors, shielded structures, rooms, and data racks.

Quick Links

Stay Informed

Subscribe for exclusive updates

and insights from Gaven Industries.

Copyright © 2024 Gaven Industries Inc. All Rights Reserved.